In the competitive mattress manufacturing industry, optimizing packaging efficiency is crucial for reducing costs, improving product protection, and enhancing customer satisfaction.

By implementing workflow analysis, automation, quality control, and employee training, manufacturers can streamline their packaging process and boost overall productivity.

How Can I Assess My Current Packaging Workflow?

Before making improvements, it is essential to evaluate your current mattress packaging process.

Identifying inefficiencies and bottlenecks allows you to optimize the workflow for better productivity.

Steps to Evaluate Your Workflow:

✔ Map Out the Entire Packaging Process: Identify each stage, from preparation to final sealing.

✔ Analyze Processing Times: Measure how long each step takes and look for delays.

✔ Identify Bottlenecks: Pinpoint areas where slowdowns occur, such as manual wrapping or labeling errors.

✔ Engage With Staff: Gather feedback from workers on potential improvements.

Why Is Using High-Quality Packaging Materials Important?

The right materials ensure mattress protection, reduce packaging errors, and improve workflow efficiency.

Inferior materials can lead to damage, product returns, and slower processing times.

Recommended Materials for Mattress Packaging:

| Material Type | Benefits |

|---|---|

| Plastic Films | Moisture-resistant and flexible for easy wrapping |

| Protective Covers | Shields mattresses from dust and dirt |

| Heavy-Duty Sealing Tape | Ensures strong, secure seals for transit |

| Biodegradable Packaging | Reduces environmental impact while maintaining protection |

How Can Automation Improve Efficiency?

Automation minimizes manual labor, increases speed, and ensures consistent packaging quality.

Automated machines handle wrapping, sealing, and labeling faster and with greater precision than manual processes.

Types of Automated Packaging Machines:

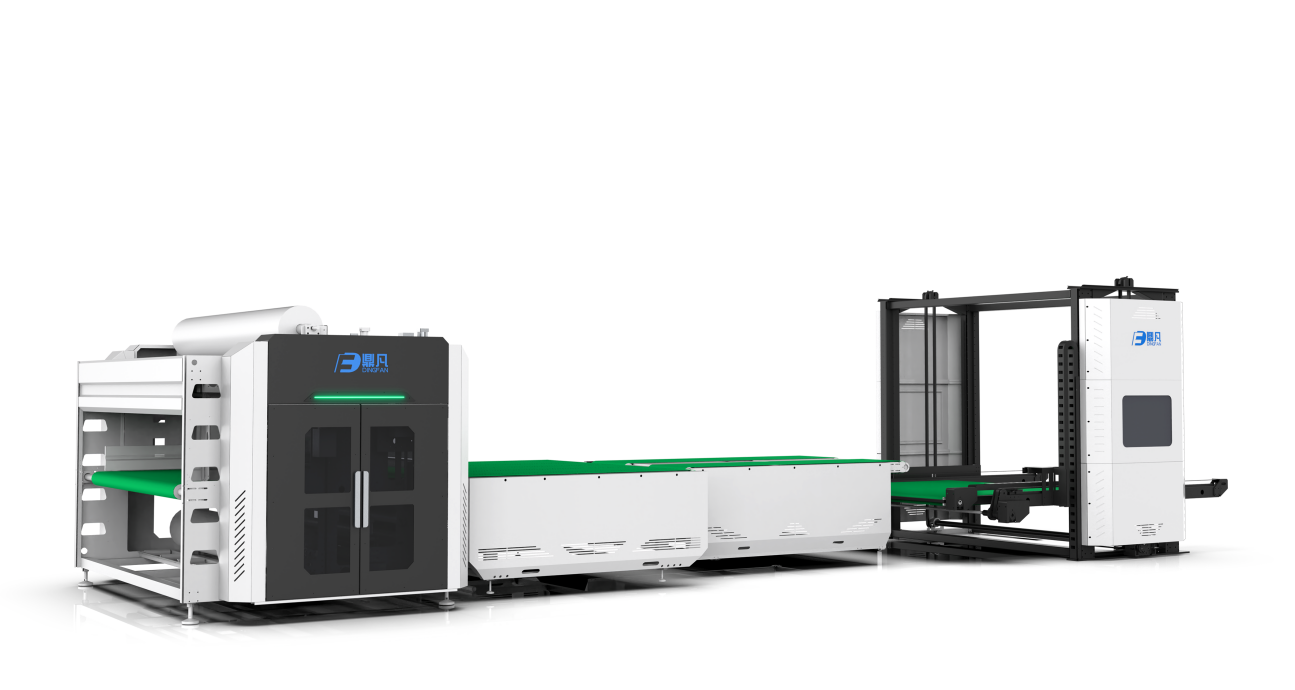

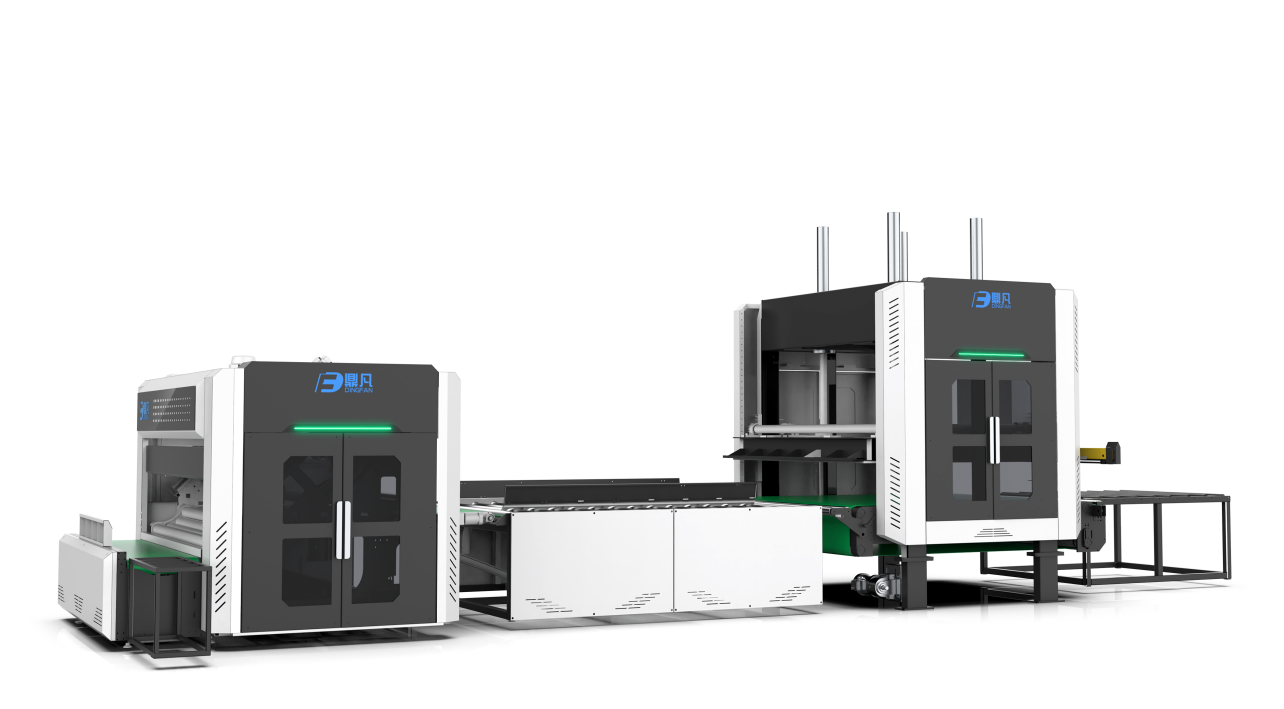

✔ Automatic Wrapping Machines: Reduce time spent on manual wrapping.

✔ Compression & Roll-Pack Machines: Optimize space for shipping and storage.

✔ Automated Labeling Systems: Improve accuracy and reduce labeling errors.

What Training Does My Workforce Need?

Even with automation, well-trained employees are essential for efficiency.

Proper training enhances productivity, reduces errors, and extends machine lifespan.

Key Training Areas:

- Machine Operation & Maintenance: Ensure employees can use and troubleshoot equipment.

- Efficient Packaging Techniques: Teach best practices for wrapping and sealing.

- Quality Control Protocols: Help workers detect packaging defects early.

How Can Workspace Layout Impact Efficiency?

A well-organized workspace minimizes movement and reduces unnecessary handling time.

An optimized layout improves workflow, reduces fatigue, and increases processing speed.

Workspace Optimization Tips:

✔ Arrange Workstations Logically: Reduce the distance between packaging steps.

✔ Store Materials Nearby: Keep packaging supplies within easy reach.

✔ Use Ergonomic Equipment: Reduce strain and increase worker comfort.

How Can Quality Control Measures Improve Efficiency?

A strong quality control process prevents errors and reduces rework, saving time and resources.

Regular inspections at different packaging stages ensure that every mattress meets quality standards.

Quality Control Checklist:

✔ Check for Wrapping & Sealing Defects: Ensure packaging is secure.

✔ Verify Label Accuracy: Avoid shipping errors.

✔ Test Compressed Packages: Confirm stability and durability.

How Does Customer Feedback Help Improve the Process?

Customer feedback highlights areas for improvement in packaging quality and durability.

Listening to customers helps refine packaging methods and enhance product presentation.

How to Collect & Implement Feedback:

✔ Monitor Return Rates & Complaints: Identify packaging-related issues.

✔ Conduct Surveys: Ask customers about packaging satisfaction.

✔ Make Adjustments Based on Data: Improve packaging based on insights.

Conclusion

Improving mattress packaging efficiency requires evaluating workflow, investing in quality materials, adopting automation, training employees, and implementing quality control. By optimizing each aspect of the process, manufacturers can reduce costs, increase productivity, and deliver better-packaged products to customers.

A well-structured, efficient packaging system not only boosts operational performance but also enhances brand reputation and customer satisfaction.

Get in touch with us for tailored solutions! We look forward to collaborating with you and shaping a brighter future together!

📞 | WhatsApp:+86 15220512074

📧E-mail:zhongliantec@gmail.com

Web | Link:mattressmachineryzl.com