Traditional mattress edge sewing was slow, labor-intensive, and prone to inconsistency.

Modern mattress edge sewing machines increase speed, precision, and design flexibility—transforming the way factories produce high-quality mattresses.

In this article, I’ll walk through the evolution of edge sewing in mattress production, explore today’s advanced machines, and explain how they impact quality, efficiency, and cost.

What Problems Did Traditional Edge Sewing Have?

Before automation, edge stitching required skill, time, and constant attention.

Manual and early mechanical edge sewing was inconsistent, physically demanding, and slow—limiting factory growth and product reliability.

Key Challenges in Traditional Methods

1. Labor Dependence

Operators had to manually guide tape and stitching arms. The process was tiring and required constant vigilance.

2. Inconsistent Stitching

Even skilled workers would produce variations in stitch spacing or depth, affecting mattress edge strength and visual quality.

3. Time Consumption

Manual edge sewing took up to 12–15 minutes per mattress, limiting daily output to around 40–60 pieces per line.

| Problem | Impact on Factory Output |

|---|---|

| Manual Operation | Slower cycle times |

| Quality Inconsistency | More rework and customer complaints |

| Fatigue & Turnover | High labor turnover and injuries |

The industry needed a solution that could boost speed without sacrificing quality.

How Have Edge Sewing Machines Evolved?

The shift from hand-guided tape machines to digital servo systems has reshaped production lines.

New machines offer servo-driven tape guidance, automated lifting arms, and programmable stitch settings—greatly improving consistency and output.

Key Technological Breakthroughs

Servo Motor Control

Precise stitch control with less vibration. Servo motors also reduce power usage and noise levels.

PLC Programming

Operators can save multiple stitching programs, switch between mattress sizes, or change stitch lengths with one touch.

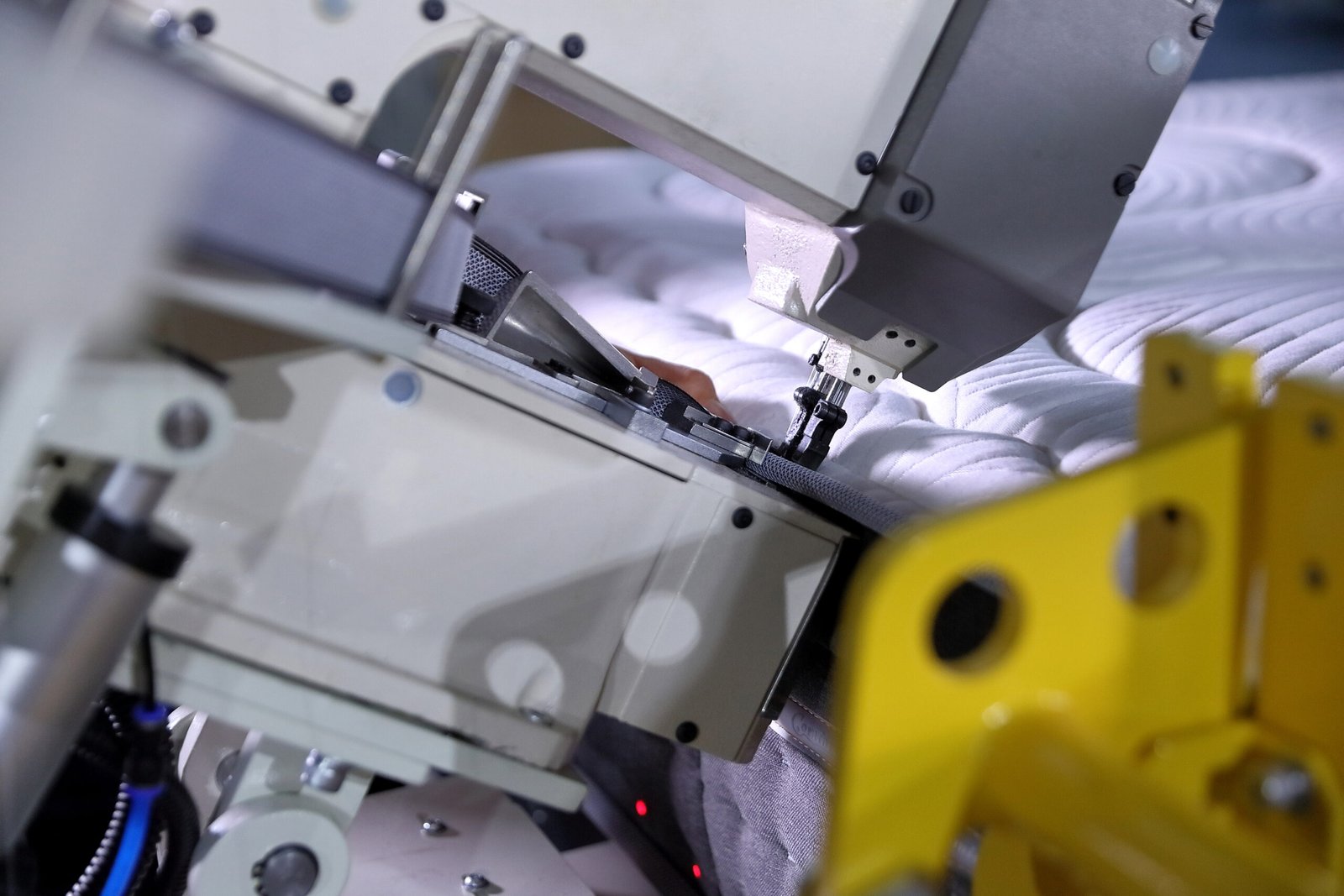

Edge Compression Arms

Automated rollers press and align edge layers before sewing, reducing skipped seams and improving fit.

| Feature | Result in Production |

|---|---|

| Servo Motor | Precision stitching and energy savings |

| Touchscreen + PLC | Fast switch between mattress models |

| Compression Guidance | Straighter, tighter edge seams |

What Types of Modern Edge Sewing Machines Exist?

Depending on your production scale and customization needs, different models serve different purposes.

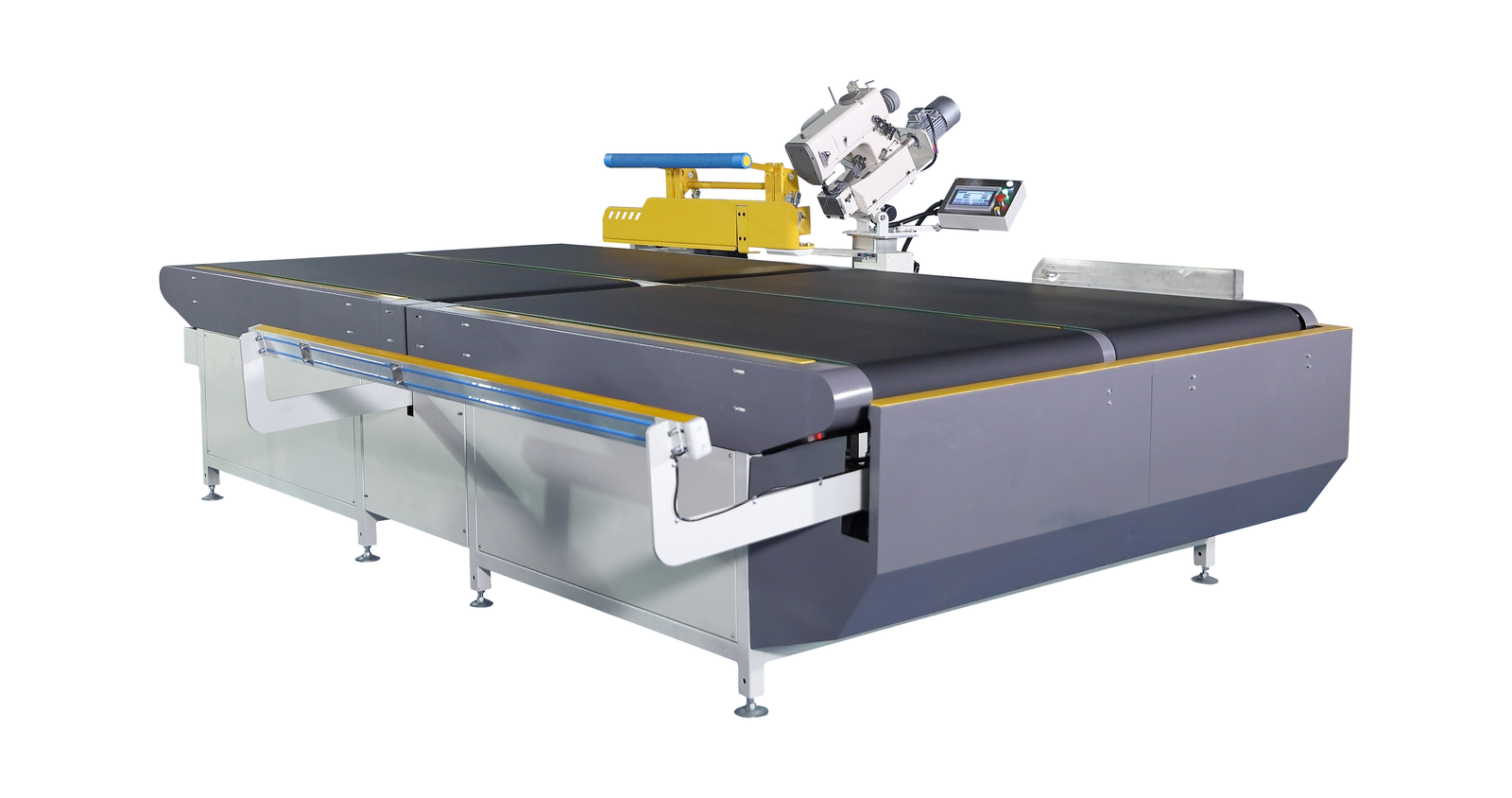

Today’s market includes semi-automatic, fully automatic, and hybrid edge sewing machines—each offering unique benefits.

Comparison Table

| Machine Type | Best For | Automation Level |

|---|---|---|

| Semi-Automatic | Low-volume, flexible production | Medium |

| Fully Automatic | High-speed, high-consistency factories | High |

| Hybrid (With Quilting) | Combined edge + panel assembly systems | Medium–High |

Fully Automatic Edge Sewing Example:

- Auto tape feeding & cutting

- Dual-needle synchronous stitch head

- Edge pressing + folding + stitching in one step

Output: Up to 180–250 mattresses/day per machine

What Features Make These Machines So Efficient?

Modern machines are more than just faster—they’re smarter.

Edge sewing machines now include programmable controls, multi-language touchscreens, safety sensors, and auto-cut functions.

Top 5 Must-Have Features

1. Programmable Stitching Patterns

Pre-save multiple SKUs. Operators switch patterns without manual reset.

2. Auto Tape Cutter

Ends the sewing job cleanly without scissors. Saves 5–10 seconds per mattress.

3. Pneumatic Foot Lift

Speeds up start/stop cycles and reduces operator fatigue.

4. User-Friendly Interface

Even entry-level staff can learn machine use within hours.

5. Real-Time Diagnostics

If a needle breaks or thread tension drops, alerts are displayed instantly.

| Feature | Efficiency Impact |

|---|---|

| Digital Pattern Recall | Faster setup, fewer errors |

| Auto Cut & Lift | Saves time per mattress |

| Safety Sensors | Prevents needle jams or injury |

How Do These Machines Improve Quality and Consistency?

Speed is great—but quality must come first.

Advanced edge sewing machines eliminate human error and provide tight, uniform stitching on every unit.

Consistency Benefits

- Stitch spacing controlled by motor, not hand

- Edge fabric held by guide rollers

- Programmed motion keeps alignment even at 2,000+ SPM

Quality Control Perks

- Fewer skipped stitches or twisted seams

- Less mattress rejection from finishing line

- Stronger side reinforcement and edge hold

| Quality Metric | Manual Method | Modern Machine |

|---|---|---|

| Stitch Gap Variation | ±2.5mm | ±0.2mm |

| Edge Misalignment Rate | 8–10% | <1% |

| Repeatability | Low | High |

These machines help manufacturers meet international standards and reduce post-delivery complaints.

Are They Worth the Investment?

Yes—especially when you consider total lifetime cost.

Modern edge sewing machines reduce labor, increase daily output, and reduce defects—all of which pay off within 12–18 months.

Cost Breakdown Example

| Category | Manual Line | Auto Edge Machine |

|---|---|---|

| Daily Output | 50–80 units | 150–220 units |

| Operator Headcount | 3–4 people | 1–2 people |

| Labor Cost/Month | $2,000–$3,500 | $1,200–$2,000 |

| Defect/Rework Rate | 6–8% | <1% |

Even if the initial machine cost is $8,000–$15,000, the payback happens quickly with lower labor and higher throughput.

Conclusion

Innovative mattress edge sewing machines combine speed, quality, and smart design—making them essential for any factory aiming to scale production while maintaining top-tier product standards.

Get in touch with us for tailored solutions! We look forward to collaborating with you and shaping a brighter future together!

📞 | WhatsApp:+86 15220512074

📧E-mail:zhongliantec@gmail.com

Web | Link:mattressmachineryzl.com