What Types of Mattress Spring Machines Are Available on the Market?

In the mattress industry, the type

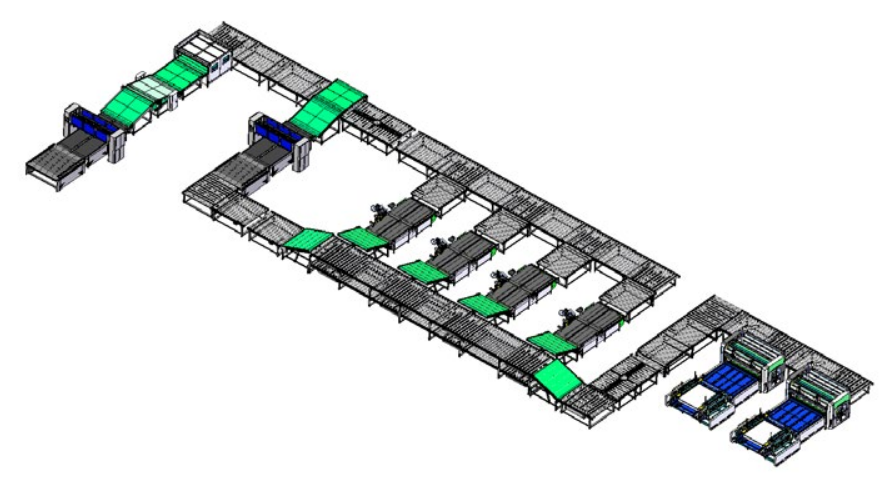

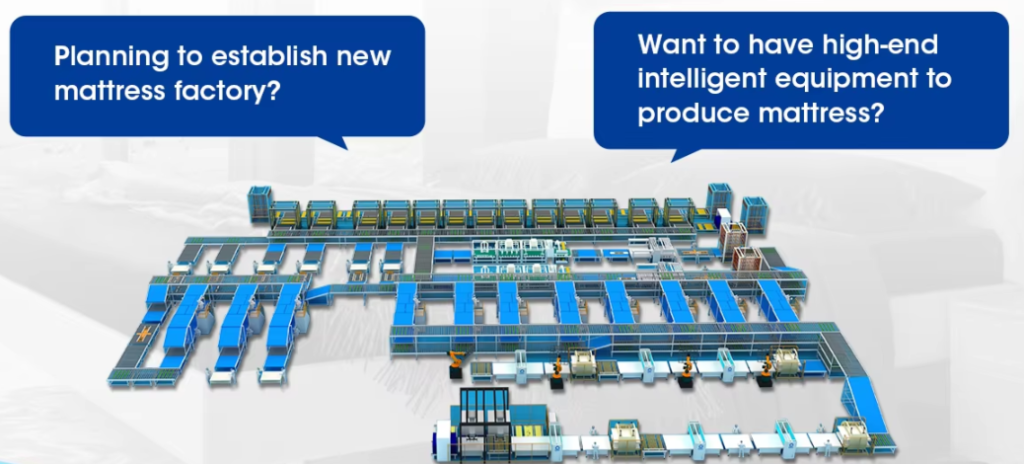

Our mattress machinery line comprehensively covers the four essential processes of mattress manufacturing: spring production, quilting, edge sealing, and final packaging. With over 36 equipment categories and more than 100 machine models, we offer a complete, end-to-end solution for mattress production—designed to meet the needs of manufacturers seeking high-efficiency and scalable production.

In terms of pricing, we provide tailored quotations based on each customer’s specific equipment requirements, ensuring a cost-effective and suitable solution.

Automated & Precise Pocket Spring Production with Customizable Specifications and Minimal Labor Involvement.

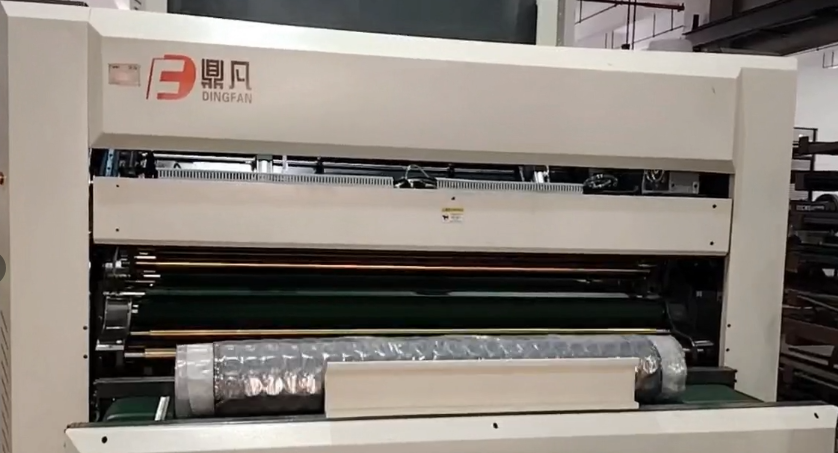

Automated & Accurate Quilting for Mattress Panels with Flexible Patterns and High-Speed Performance.

Smooth & Durable Tape Edge Sewing for Mattresses with Adjustable Speed and Precise Corner Turning.

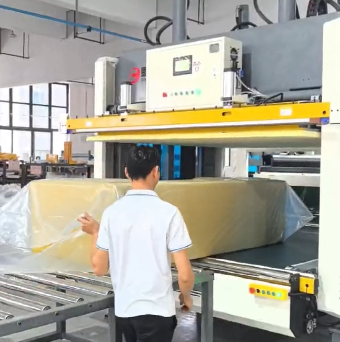

Versatile Packaging Solutions for Mattresses, Roll-Pack and Sofa Compression with High Efficiency and Compact Design.

Foam blocks, fabrics, non-woven materials, coils, and accessories (zippers, handles, labels) are prepared and cut to size. This ensures efficient flow in the later production stages.

Using pocket spring or Bonnell spring machines, steel wires are coiled, heat-treated, and assembled into spring cores. These can be single-zone or multi-zone depending on mattress design.

For pocket spring mattresses, automated gluing machines apply hot-melt adhesive to fix spring rows together and shape the mattress core.

CNC or manual foam cutting machines are used to cut foam layers, latex, or memory foam to match the mattress size and structure.

Quilting machines stitch fabric layers with foam or fiber filling into top and bottom panels. Pattern, stitch length, and density are customizable.

Quilted panels are cut to mattress size. At the same time, side borders are sewn (including handles, air vents, zippers, logos) using industrial sewing machines.

All parts (spring core, foam layers, quilted panels, borders) are assembled. Tape edge machines sew the top and bottom panels together with the borders to form the complete mattress.

Brand labels, care instructions, or custom embroidery are attached. Final quality checks are performed to ensure stitching is neat and dimensions are accurate.

Packaged mattresses are barcoded, stored in the warehouse, and loaded for delivery to retailers, distributors, or direct customers.

Mattresses are sent through compression or roll-packing machines for space-saving packaging. Packaging type depends on product and shipping needs.

Discover how our automated mattress machines can help you reduce production time, boost efficiency, and deliver faster to your market. Let us customize a solution for your factory.

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation. Take the example of booking a tall container of products:

In the mattress industry, the type

How Much Production Capacity Can Ma

Can One Machine Produce Different T

What Are the Power Requirements for

ZL Mattress Machinery is a trusted high-tech manufacturer with over 10 years of industry expertise. From spring production to quilting, edge sewing, and packaging, we offer a full range of mattress manufacturing solutions designed for efficiency, stability, and cost-effectiveness.

Complete Product Line

Over 100 models covering the entire mattress production process—spring machines, quilting machines, tape edge machines, and roll-packing machines.

Strong R&D and Customization

Our experienced engineering team provides continuous product innovation and supports customized solutions tailored to your factory needs.

High-Speed & Stable Operation

Our machines are built for long-term, high-volume operation with fast speeds and low maintenance requirements.

Professional After-Sales Support

From on-site installation and training to spare parts and remote troubleshooting, we ensure your production runs smoothly at all times.

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation. Take the example of booking a tall container of products:

WhatsApp us

Tell us what you need — we’ll handle the rest.