Our Mattress Border Sewing Machines offer advanced, efficient solutions designed for mattress manufacturing. From automatic tape edge machines to semi-automatic border sewing machines.

Mattress Border Sewing Machines

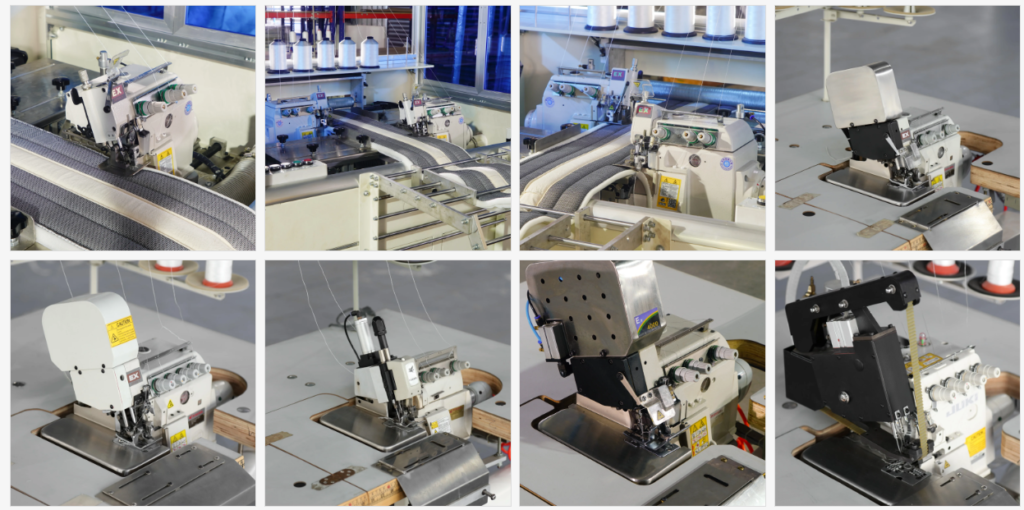

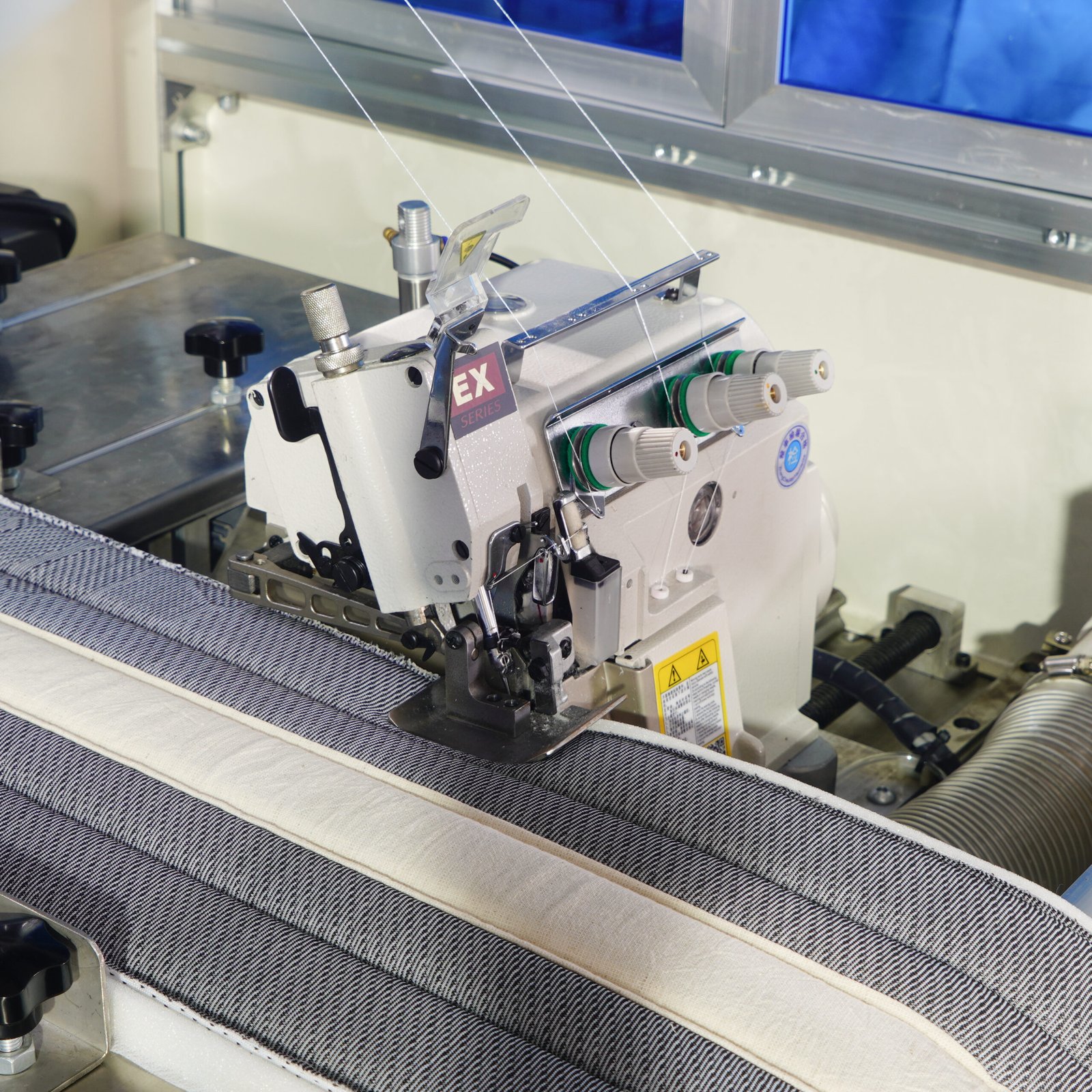

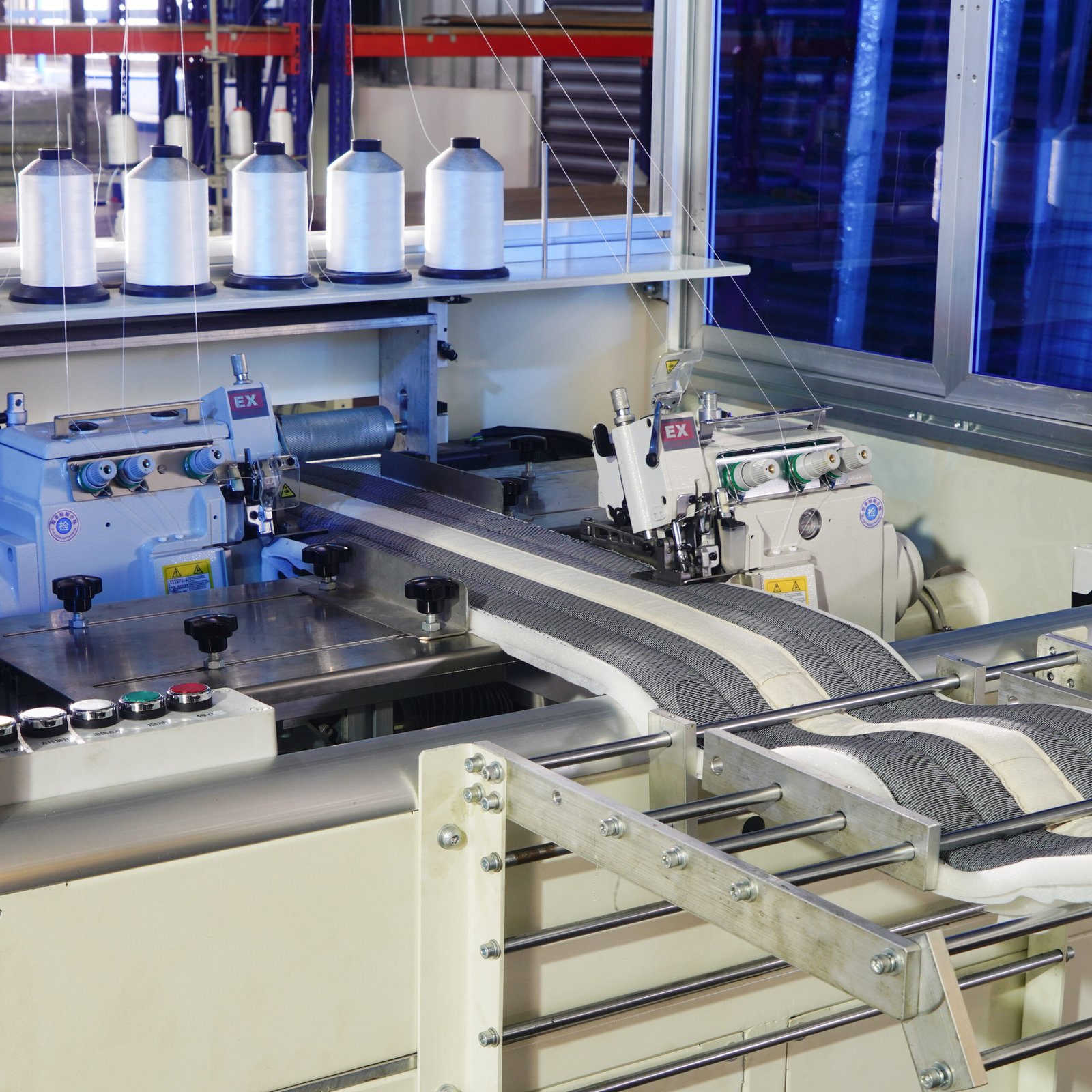

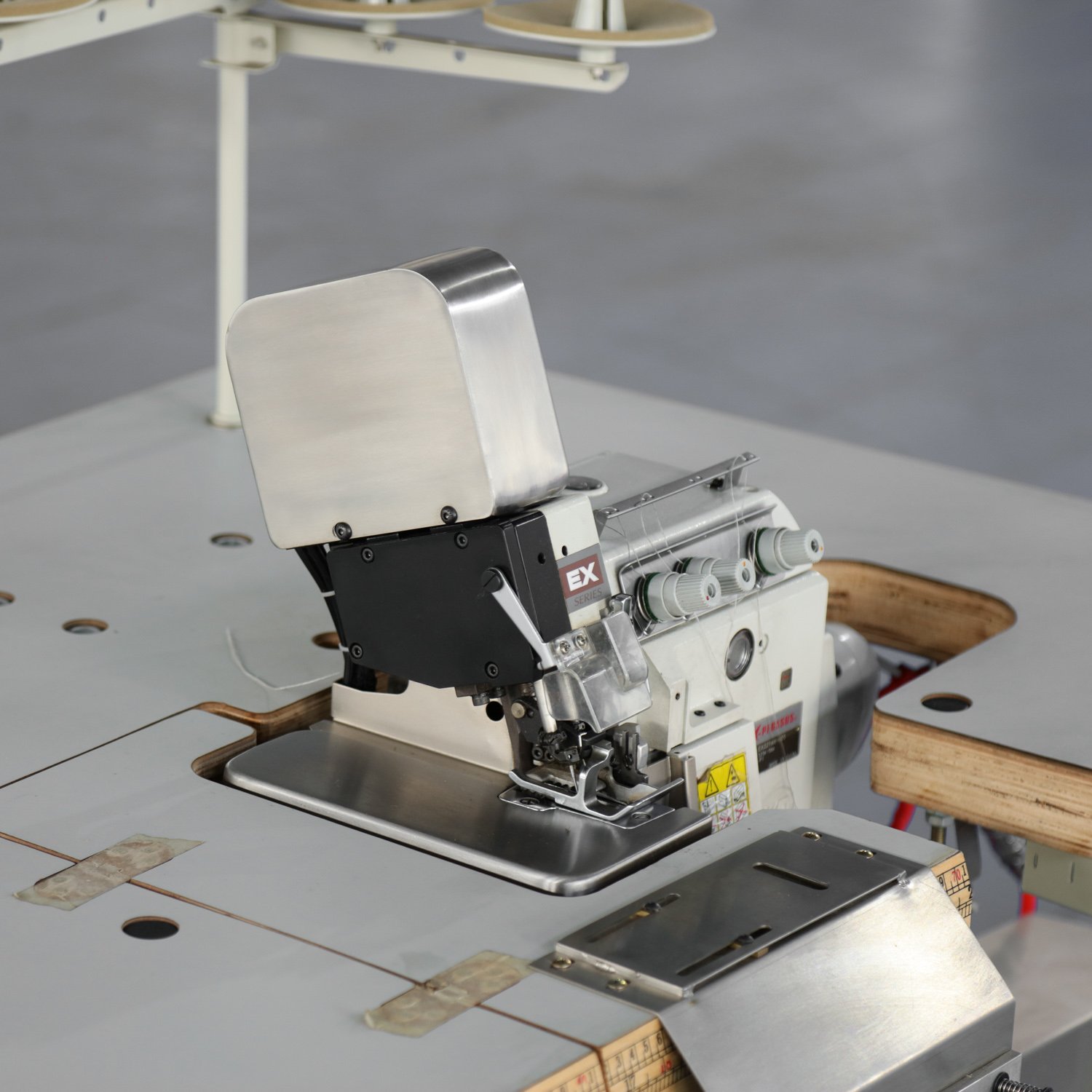

Our border sewing machine series offers a comprehensive range of solutions for mattress border processing.

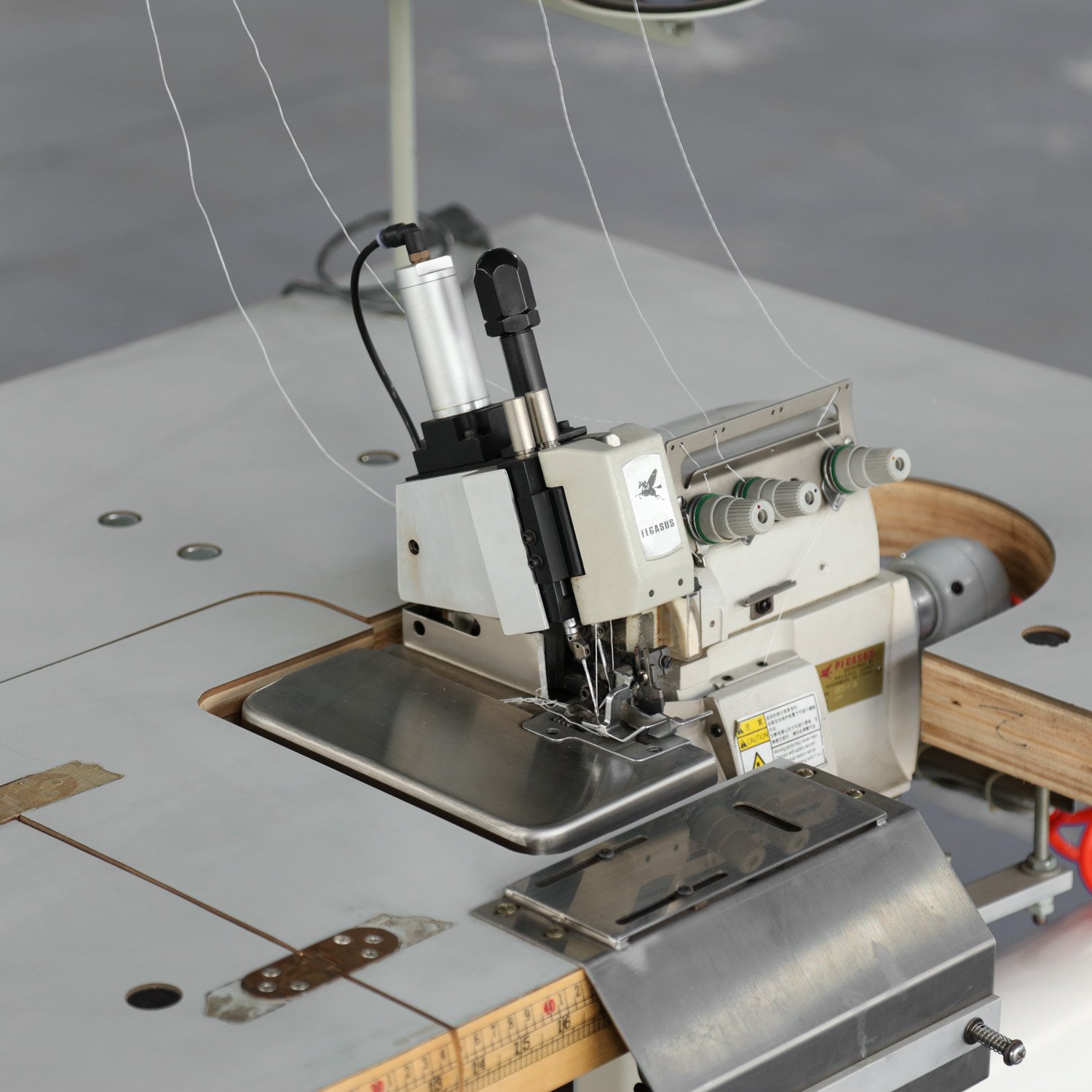

Four sewing heads work independently or simultaneously;

ideal for high-precision pattern sewing and decorative

stitching.

- Decorative stitching and pattern sewing

- Speed:1-5 m/min

Automated & Accurate Quilting for Mattress Panels with Flexible Patterns .

- Automated border marking and cutting

- Speed:4-6 mattress borders/min

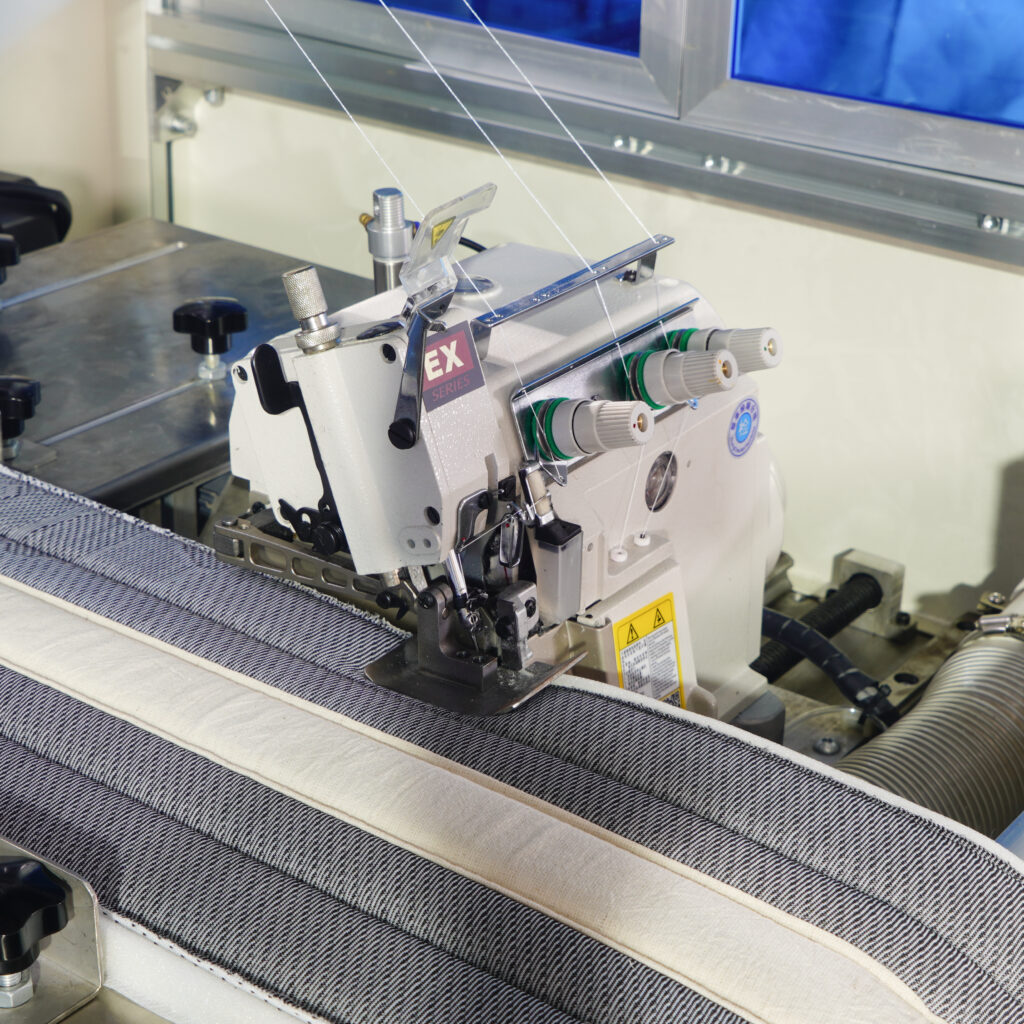

Dual-head operation; high productivity for large-scale

border flanging.

- High-volume flanging production

- Speed:15-30 m/min

Suitable for straight-line sewing of bone strips, zippers, and trims; multi-functional applications.

- Mini spring,high-compression, high-speed, and sofa pocket spring machines

- Speed:7 m/min

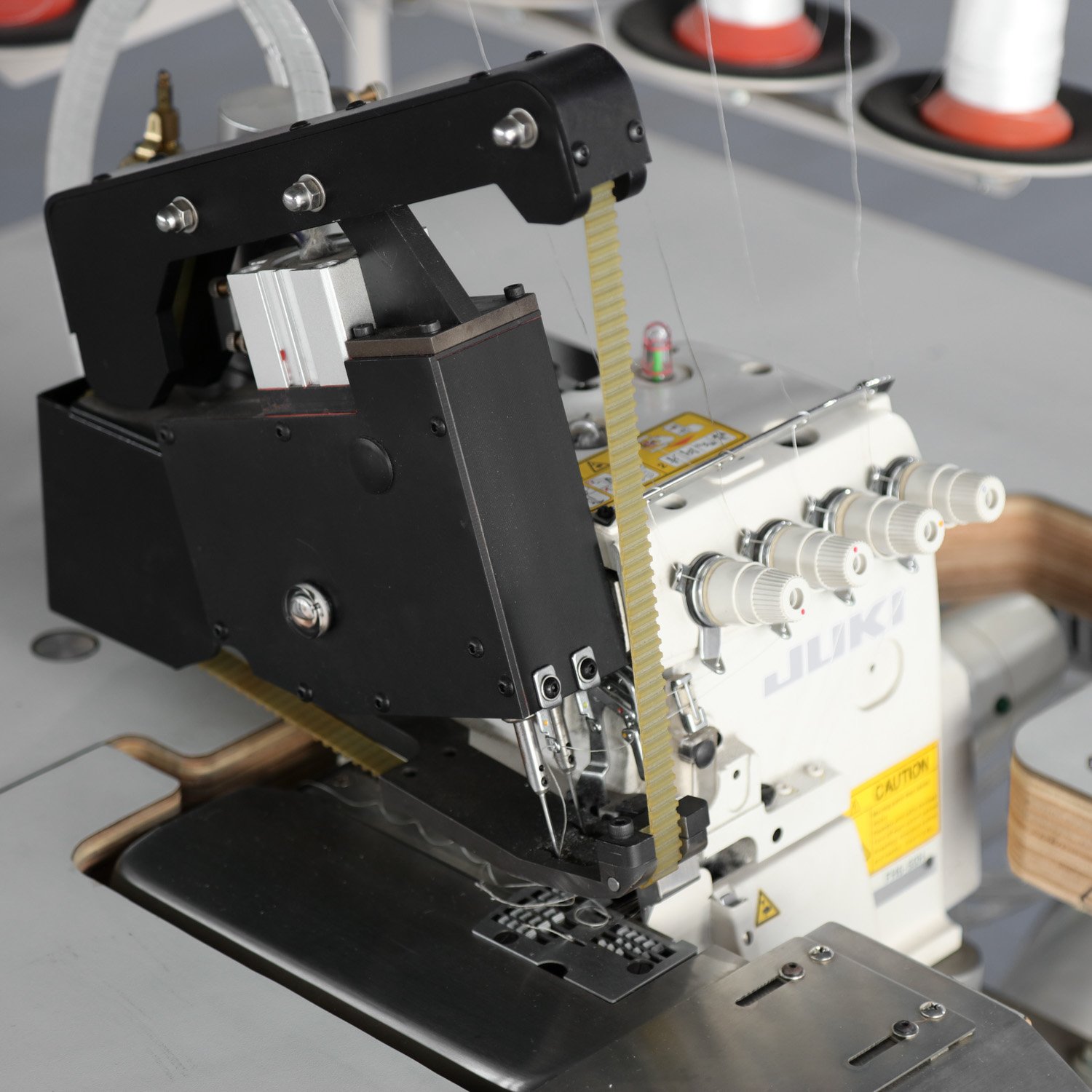

Combines sewing and cutting; ideal for continuous production with efficient trimming.

- Integrated sewing and cutting solutions

Multi-functional; performs ribbon sewing, bone insertion, and zipper attachment in one process.

- Integrated sewing and cutting solutions

Suitable for straight-line sewing of bone strips, zippers, and trims; multi-functional applications.

- Mattress three-border tape sewing and visual

Combines sewing and cutting; ideal for continuous production with efficient trimming.

- Decorative stitching and pattern sewing

- Speed:10-14.4m/min

Mattress Sewing Aid Machines

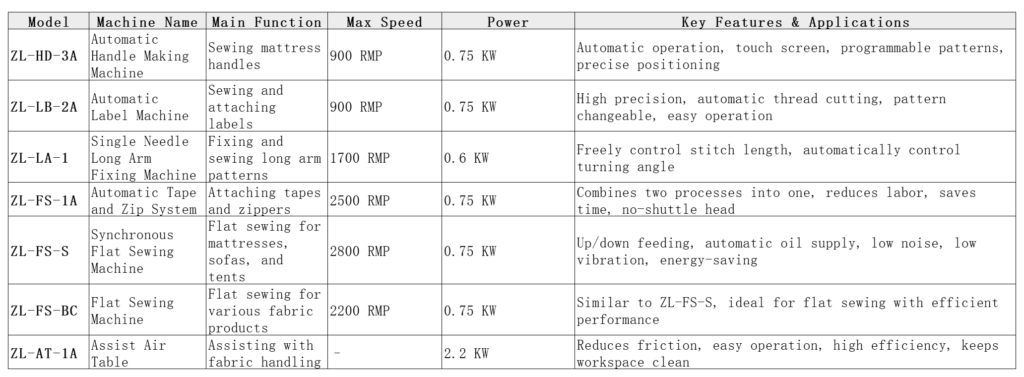

Handle & label sewing: ZL-HD-3A, ZL-LB-2A Tape & zipper application: ZL-FS-1A

Flat sewing applications: ZL-FS-S (high speed), ZL-FS-BC (standard speed) Complex pattern sewing: ZL-LA-1

Fabric handling support: ZL-AT-1A

ZL-HD-3A Automatic Handle Making Machine

ZL-LB-2A Automatic Label Machine-2A

ZL-LA-1 Single Needle Long Arm Fixing Machine

ZL-FS-1A Automatic Tape And Zip System

ZL-FS-S Synchronous Flat Sewing Machine

ZL-FS-BC Flat Sewing Machine

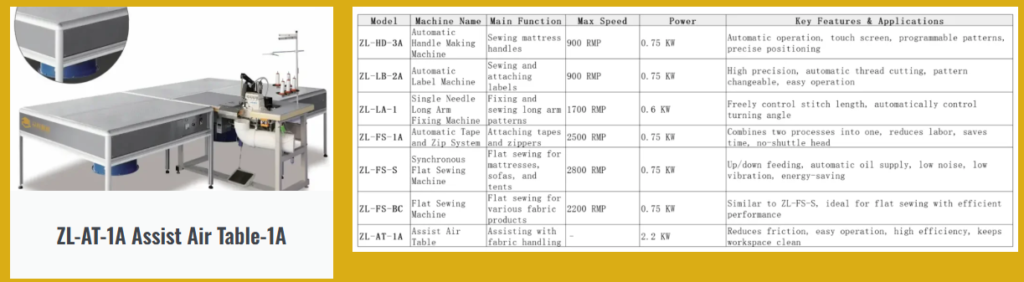

ZL-AT-1A Assist Air Table-1A

Mattress Flange Machines

ZL-AFG-1A Automatic Flange Machine

ZL-FG-5A Flanging Machine 5A

ZL-FG-5B Flanging Machine 5B

ZL-FG-7A Extra Heavy Flanging Machine (With Belt)

ZL-FG-8A Extra Heavy Flanging Machine

We are proud to partner with clients worldwide, providing efficient, reliable, and cost-effective mattress and furniture packaging solutions.

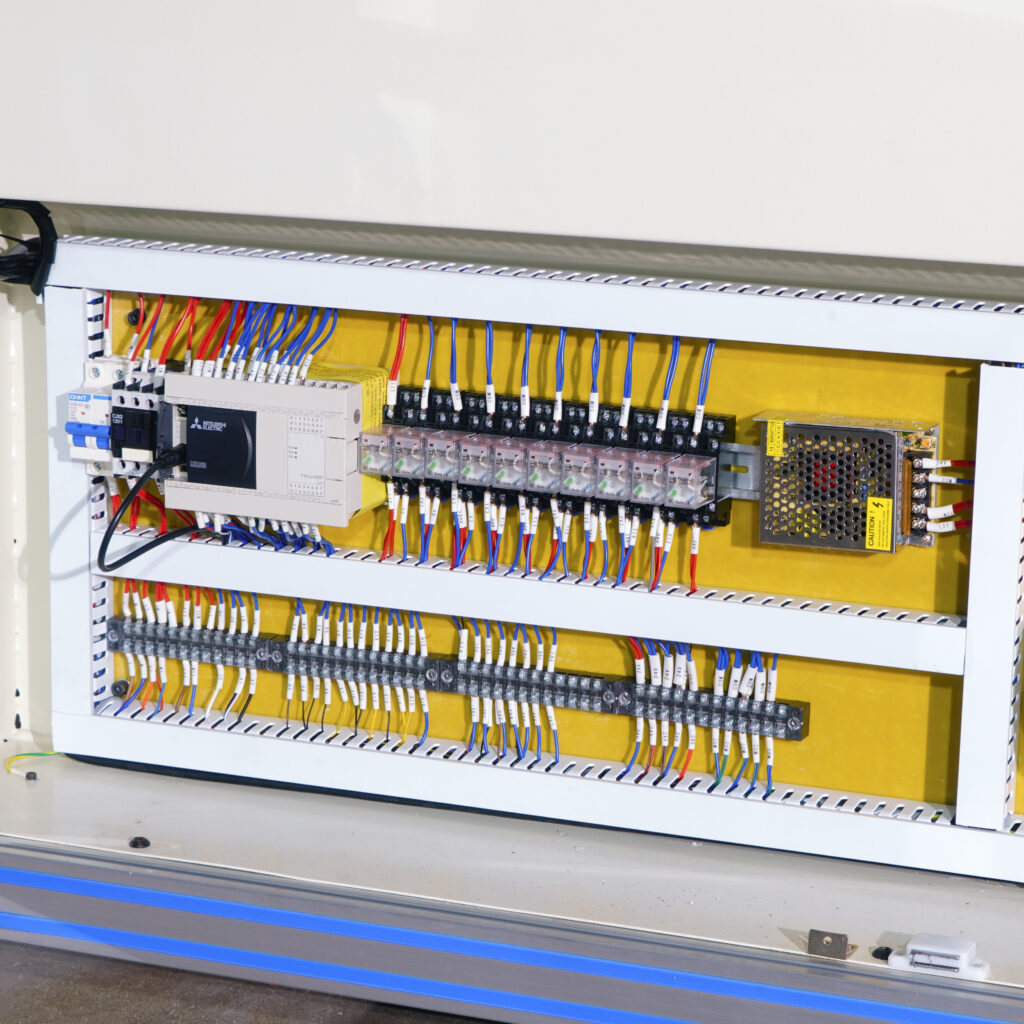

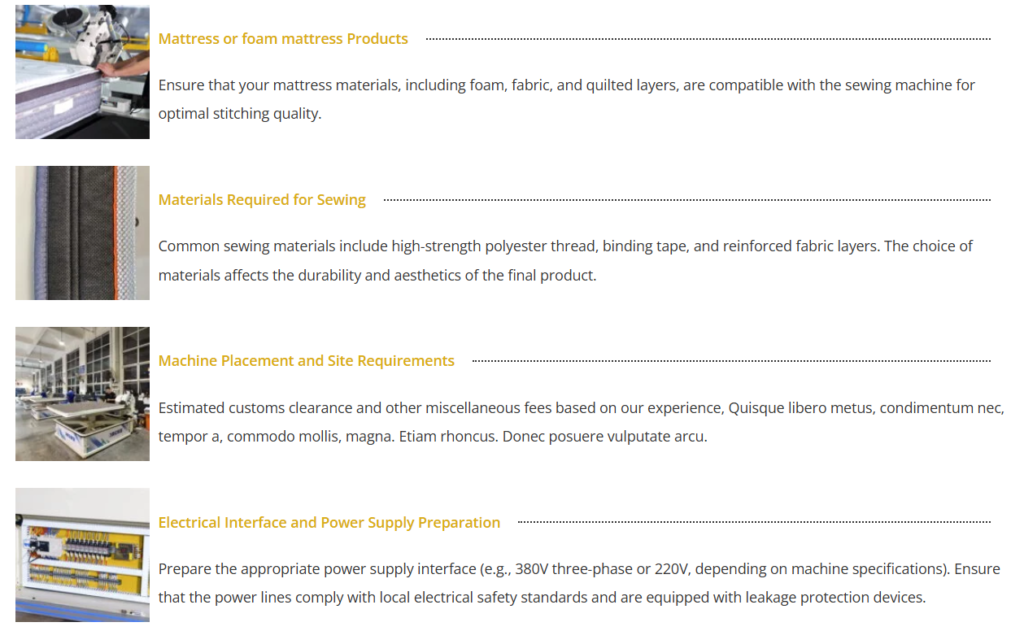

To ensure smooth installation and efficient operation of the mattress sewing machine, please prepare the following materials and installation environment in advance.

Please note that the actual timeline may vary depending on site conditions, preparation adequacy, and logistics. Below is a typical process outline after receiving the mattress sewing machine.

Overall Design Principles of Multi-Layer Mattress Conveying and Storage Systems

As mattress manufacturing moves toward higher automation, larger production scale, and 24-hour operation, conveying and storage systems are no longer auxiliary equipment. They have become a core part of factory architecture. In particular, multi-layer mattress

How Automated Conveying Systems Reduce Labor Costs by 40% in Mattress Manufacturing

In mattress manufacturing, labor cost is not driven only by how many workers are employed on the production line. It is driven by how often products are lifted, carried, repositioned, waited on, or corrected by

How the ZL-AHG Glue Spraying Machine Achieves Strong and Uniform Glue Point Distribution

In modern mattress manufacturing, glue spraying is no longer a simple auxiliary step. It has become a core structural process that directly affects bonding strength, durability, comfort consistency, and long-term product reliability. As mattress structures