Automatic Tape EdgingMachine ZL-TE-5B

Primarily used for mattress edge binding.

• 1. Automatic mattress flipping function reduces labor costs;

• 2. Dual-side flipping design effectively protects mattresses;

• 3. Automatic cornering function enables easier operation;

• 4. Integration of production lines to ensure efficient production of standardized products;

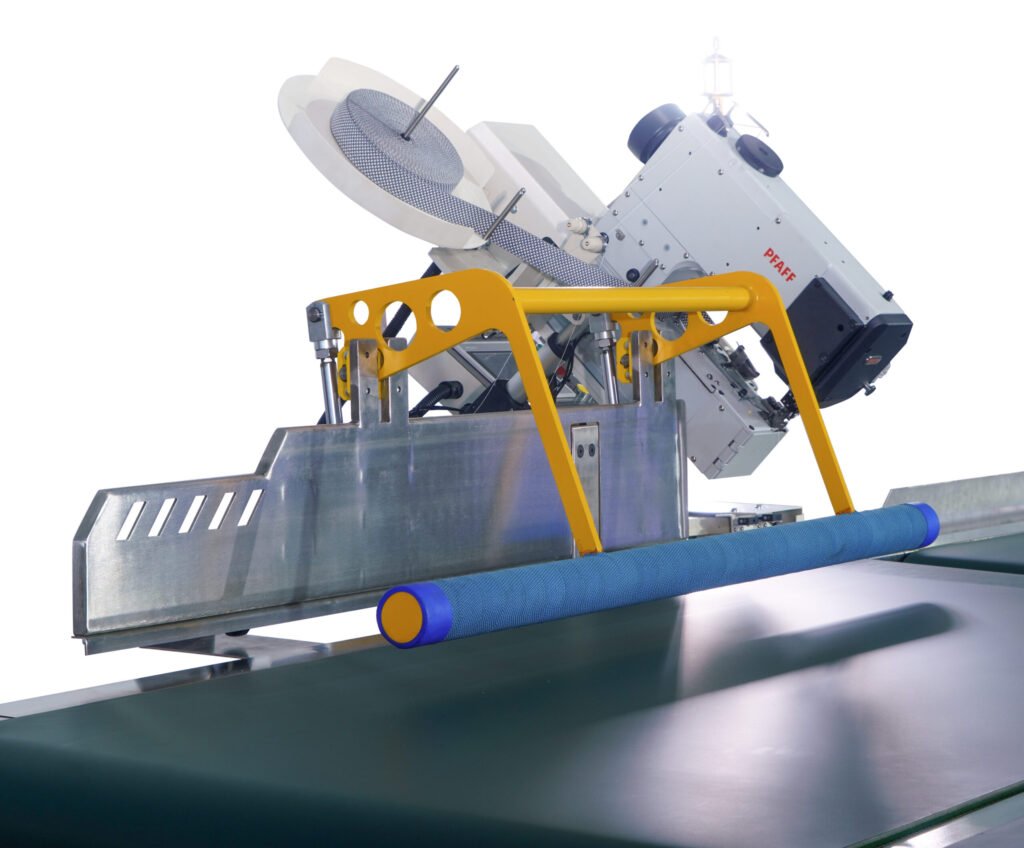

• 5. Touchscreen controls head tilt angle and lifting mechanism;

• 6. Equipped with automatic auxiliary push rods to prevent deviation;

• 7. Auto-alignment functionality;

• 8.When the mattress turns, the sewing machine head will automatically rise.

Detail For Mattress Tape Edging Machine

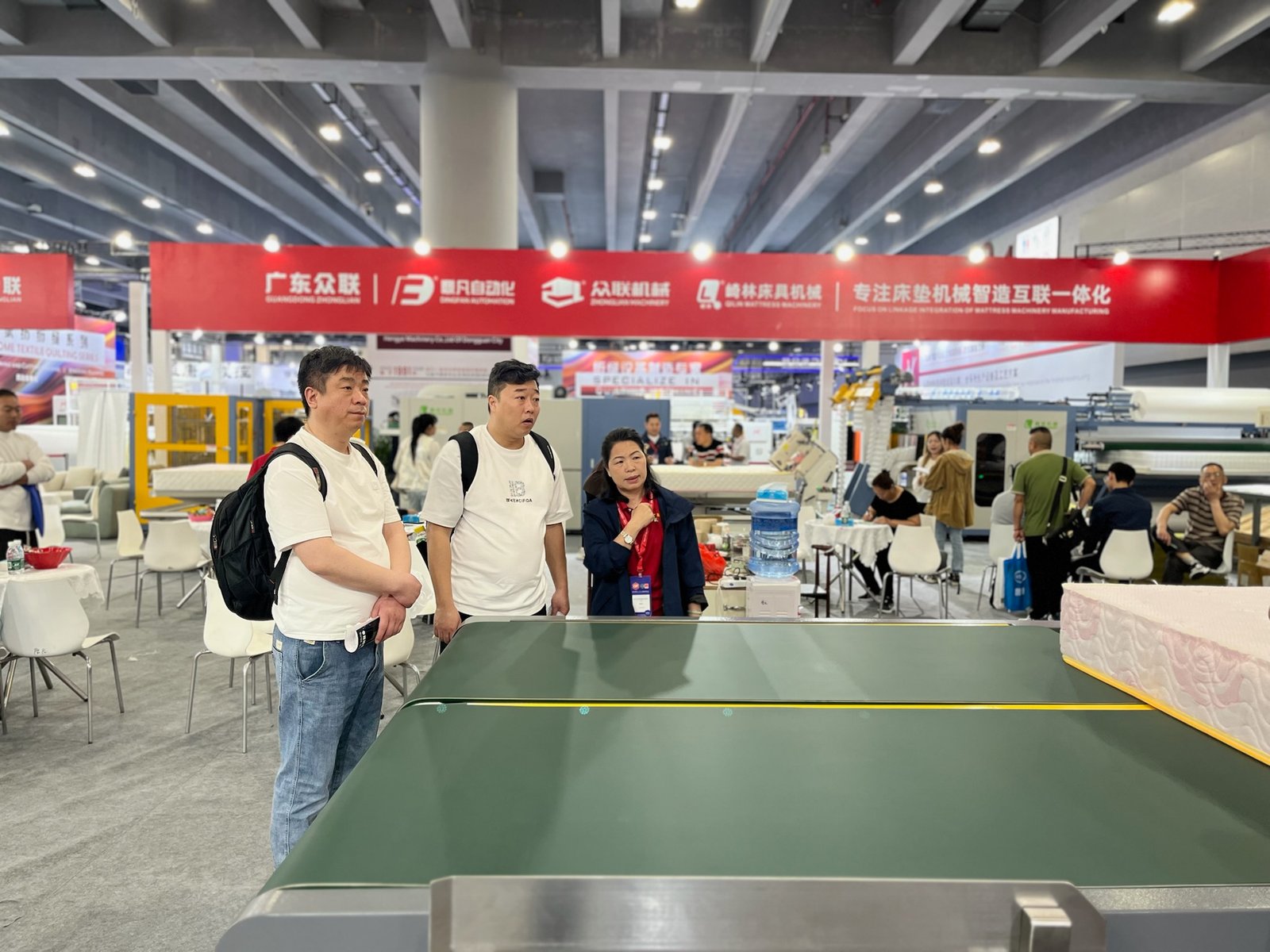

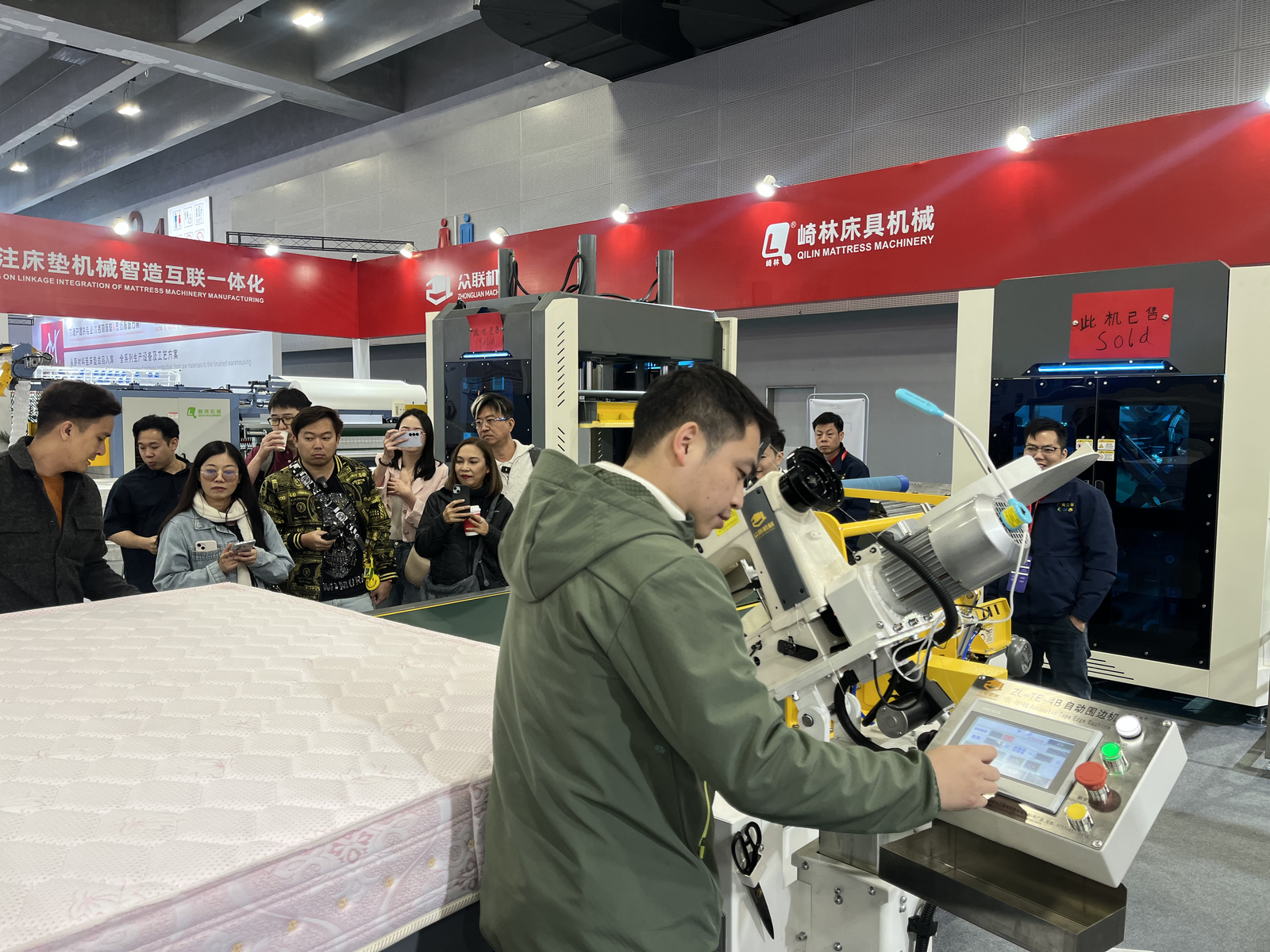

Application Of Tape Edging Machine

| Technical Specifications | |

|---|---|

| Production Efficiency | 15–20 sheets/hour |

| Sewing Thickness | 50–450mm |

| Maximum Speed | 2800 RPM |

| Stitch Length | 3–7mm |

| Machine Weight | 1500 kg |

| Rated Power | 3 kW |

| Rated Power Supply | 3 Phase 380V 50/60Hz |

| Rated Air Pressure | 0.6–1.0 MPa |

| Frame Size (L×W×H) | 4300 × 3000 × 900 mm |